20/7/2022

Many countries throughout the world are deploying hydrogen fuel cell vehicles (HFCV), including cars, buses, trucks, trains, marine vessels and aeroplanes. A fire incident such as a flammable liquid spill, hydrogen jet fire and smouldering fire, could cause a hydrogen tank rupture.

The current onboard composite high-pressure tanks have a low fire-resistance rating (FRR) of 4-8 min in gasoline/diesel/hydrogen fires with intensity HRR/A=1-4 MW/m2. An incident in a confined space like a tunnel with HFCV could escalate to fire and lead to a catastrophic onboard tank rupture with consequences for life, property and the built environment. The severity of an incident and the value of risk will depend on the storage tank volume and pressure, tunnel and traffic parameters.

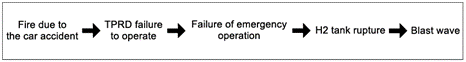

Figure 1. The sequence of events leads to tank rupture in a fire and results in the blast wave [1].

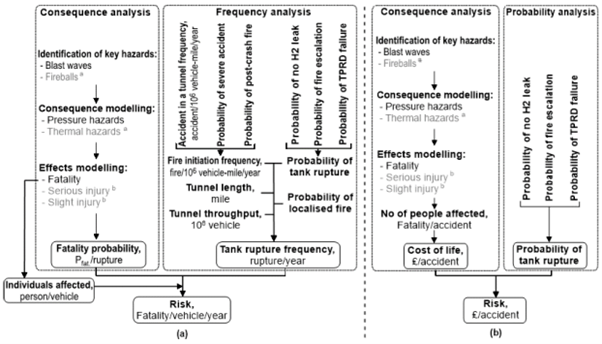

Considering previously unavailable knowledge on the risk and hazards of catastrophic hydrogen tank rupture in a fire inside a tunnel, Efectis, in collaboration with HySAFER, Ulster University, developed a quantitative risk assessment (QRA) methodology for hydrogen-powered vehicles in the road tunnel. This QRA study is performed to address the risk associated with the blast waves after the tank rupture in the tunnels. The aim is to investigate the impact of FRR of onboard hydrogen composite high-pressure tanks on the level of risk and its acceptance for hydrogen powered vehicles in a tunnel environment. The risk is defined in two ways: fatalities per vehicle per year and the cost per accident.

Figure 2. The QRA methodology flowchart for HFCV in a tunnel: (a) risk in terms of fatality per vehicle per year; (b) risk in terms of monetary losses per accident [1].

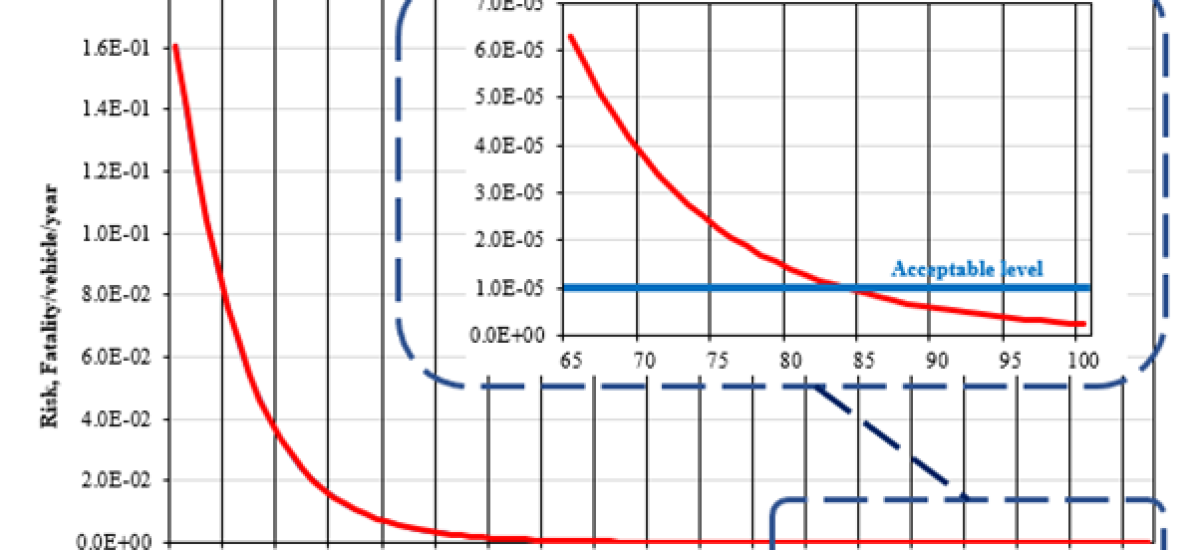

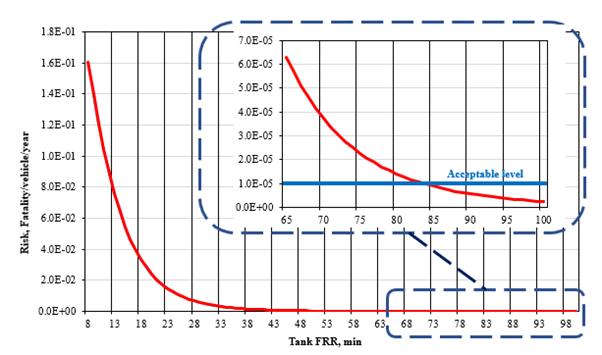

The methodology was applied to a Dublin tunnel for the case of a 62.4 L, nominal working pressure (NWP)=70 MPa hydrogen tank rupture in a fire with state of charge (SoC)=59%. The study demonstrated that for the above-mentioned thermally unprotected composite onboard storage tank, where the FRR is 6-12 minutes, the risk is 1.07 10-2 fatality/vehicle/year, which is three orders of magnitude bigger than the acceptable level. Increasing the FRR of the tank to 84 minutes reduces the risk to the acceptable level, i.e. 1.00 10-5 fatality/vehicle/year.

Figure 3. Risks as a function of hydrogen storage tank FRR in a fire for 62.4 L tank rupture at SoC=59%: (a) Risk (Fatality/vehicle/year), (b) Risk (£/accident) [1].

Efectis is able to help you for your H2 projects, analysing H2 fire risk Analysis, but also quantifying by modelling of H2 fire and its impacts on structure and equipment.

Contribution in projects:

- SUPERGEN Hydrogen and Fuel Cell Hub project (EP/P024807/1),

- FCH2 JU HyTunnel-CS (grant agreement No. 826193),

- FCH2 JU SH2APED (grant agreement No. 101007182).

For more information, please contact us by sending an email: uk@efectis.com

References

[1] H. Ingason, Y.Z. Li, Spilled liquid fires in tunnels. Fire Saf. J. 91 (2017) 399–406.

[2] H. Ingason, Y.Z. Li, A. Lönnermark, Tunnel Fire Dynamics. New York: Springer; 2015.

[3] H. Ingason, R. Hammarström, Fire test with a front wheel loader rubber tyre. 2010.

[4] V. Molkov, M. Dadashzadeh, S. Kashkarov, D. Makarov, Performance of hydrogen storage tank with TPRD in an engulfing fire, Int. J. Hydrog. Energy 46 (2021) 36581-36597.

[5] S. Kashkarov, M. Dadashzadeh, S. Sivaraman, V. Molkov 2022, QRA methodology of hydrogen tank rupture in a fire in a tunnel. 10th International Seminar on Fire and Explosion Hazards (ISFEH10), 22-27 May 2022, Oslo, Norway