2/5/2024

At the start of 2024, new building regulations became applicable in the Netherlands. In Article 4.51 of the new Building Decree a maximum size for a fire compartment is set, just as in the previous Building Decree.

Additionally, since the start of 2024 NEN 6060 or NEN 6079 are directly assigned as a method when a fire compartment exceeds the limit of 2.500 m2.

Study NEN 6079

For a large warehouse with mezzanines, Efectis Nederland has performed a study using NEN 6079 to determine the measures to be taken. NEN 6079 is a risk-oriented standard, which determines the risk of fire spreading Pos from the owner’s plot to the neighbours’ plot. The calculated probability of fire spreading Pos must be smaller than the permitted exceedance probability Pnorm.

The exceedance probability Pos of a compartment is the product of the probabilities P1,1, P2, P3 and P4 associated with that compartment where:

- P1,1 is the chance that an initially potential fire will become a local fire

- P2 is the chance that a local fire will develop into a compartment fire

- P3 is the chance that the fire-resistant partitions will fail in the event of a compartment fire

- P4 is the direct and indirect chance that the fire will spread from the failed fire-resistant separation to the neighbours. The indirect opportunity relates to transshipment to neighbours via other NEN6079 compartments.

In order to meet the functional requirement, additional measures have been taken, such as measures to reduce the risk of a fire (P1,1), a sprinkler system (P2) and the clear distance to other buildings and the plot boundaries (P3 x P4).

The resistance to fire penetration and fire spread in relation to the property boundary is part of the NEN 6079 study. The risk of fire spreading has been determined by means of radiation calculations. NEN 6079 mentions three different radiation models that can be used to determine the risk of fire spreading to neighbours. However, it is questionable whether all methods are also suitable for taller buildings. Efectis Nederland has specifically chosen worst case calculations because the high storage buildings in this situation are 26 and 30 m high.

The study shows that the calculated probability of fire spreading Pos is smaller than the permitted exceedance probability Pnorm. for the ironing facility. This demonstrates that the functional requirement regarding the limitation of fire spread has been met.

FSE study bridge

Since the warehouse was connected to another warehouse via a bridge, the study according to NEN 6079 was not straightforward. Several measures to prevent fire from spreading to the bridge and via the bridge to the distribution hub are imposed on the bridge based on the NEN 6079 study:

- the materials from which the bridge is constructed must be non-flammable

- there must be no flammable materials in the bridge (Class A2 or better according to NEN-EN 13501)

- the transportation of garments must be stopped automatically in the event of a fire alarm

- the bridge is equipped on both sides with fire-resistant doors in both directions, with a WBDBO (resistance to fire spreading from one space to another) of at least 60 minutes

- the bridge envelope is fire-resistant on both sides over a length of at least 7 meters with a WBDBO of at least 60 minutes from the inside to the outside

- the structure of the bridge is fire-resistant for at least 60 minutes with regard to collapse

In reality, not all the materials in the bridge will be non-combustible, because the conveyor system in the bridge will consist of a maximum of six chains of clothing. Therefore the effect of these combustible materials on the possibility of fire spread without sprinkler usage needed to be investigated. This was done with a small FSE study using the open source NIST zone model CFAST. The configuration was modelled to find the hot gas layer temperature and fire duration.

The results of the calculations are as follows:

- In the case of travelling fire, the fire is assumed to spread to all lines and then fire propagates along the lines. Assuming six lines are on fire simultaneously, the fire size reaches 12 MW. If the bridge compartment remains intact, the fire is expected to become under-ventilated after around 5 mins due to insufficient oxygen. The calculations show the temperature of the hot smoke layer reaches around 350oC for a short duration before the fire quenches. After around 15 mins, the temperature cools down to below 150oC.

- If the bridge enclosure fails and leads to an opening after around 5 minutes when the temperature is ~350oC, the temperature of the hot layer will rise to 500oC after around 8 mins, leading to flashover for the whole bridge compartment. As the HRR during flashover is higher than for the fuel controlled travelling fire, the expected duration of the fire will be shorter than 1 hour.

With six chains of garments a ‘travelling fire’ scenario or a ‘flashover’ scenario might occur. For both scenarios, the required 60 minutes fire resistance will be sufficient to make sure that there is no realistic possibility of fire spread.

FSE study evacuation

Since the customer sought to build a facade that does not provide fire protection, an additional study of the escape conditions at the nearest exits around the fire was performed. Due to the locations of all escape stairs which are on the perimeter of the building, any facade fire might impede a safe escape. In that case, this configuration is considered non-compliant by the building regulations.

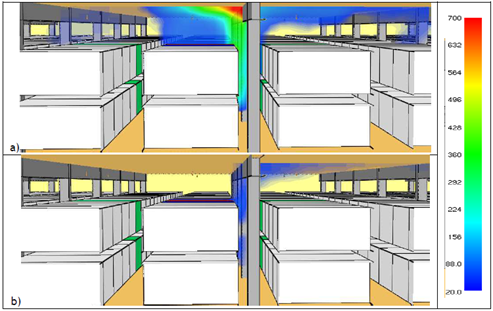

The fire was modelled with the software FDS and results were visualised for temperature, visibility and carbon monoxide concentration in particular. The influence of the geometry of the building and the location of the fire was demonstrated.

In a fire at ground level the highest plume temperature under the ceiling was 700 °C after around one minute. After ignition of the first sprinkler at 67 seconds, the smoke layer was cooled down and the stratified layer was disturbed; after around three minutes the highest temperature was lower than 100 °C at a distance of 1 m from the fire. Smoke levels, heat radiation from the smoke and carbon dioxide levels remain well below threshold at ground floor level.

The steel structured mezzanines are located at various floor levels. The study shows that smoke appears at these levels. However, because the amount of smoke is very small, there is no indication that it will cause any form of hindrance to the occupants.

The calculated environmental conditions of the investigated scenario were found tenable and occupants were not expected to be harmed during the evacuation. Having tenable conditions indicates an unlimited time to evacuate and consequently allows longer travel distances than the permitted minimum between protected escape stairs. It also allows for a facade that does not provide fire protection between the warehouse and the escape stairs.

For more information, please contact Cindy Beckers