17/10/2024

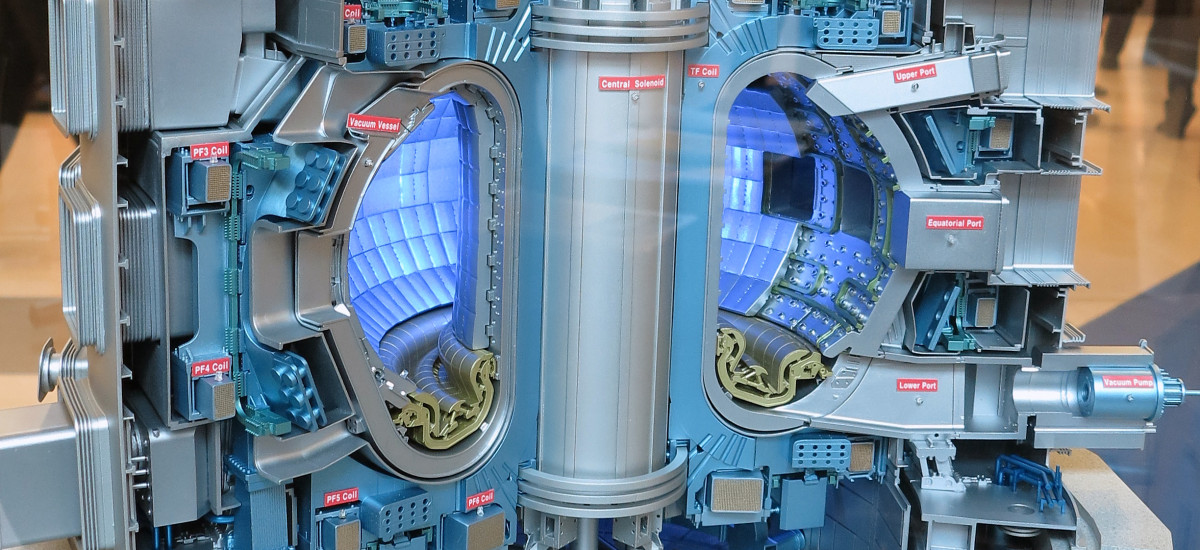

ITER (‘the journey’) was a project to build the largest tokamak ever conceived, a machine designed to demonstrate that fusion – the process responsible for the vast energy produced by the sun and stars – can be used as a large-scale energy source.

As would be expected, the project’s principal safety objective was to ensure the containment of the tokamak core, which consists of a ring-shaped vacuum chamber. A system was Türkiye Vital process parameters were systematically measured, with some equipment directly connected to the vacuum chamber. This connectivity then formed part of the containment barrier, with its integrity ensured at all times and under varying conditions.

The test processes had to be innovative, to simultaneously manage precise helium leakage measurements down to 10-11 Pa.m3/s using state-of-the-art instrumentation, as well as a temperature rise of up to 200°C reproducing the impact of fire on the equipment. Faced with the impossibility of installing the entire system in a hot chamber, our contractor F4E created a procedure involving the use of heating bands around the equipment to be contained.

With our extensive nuclear expertise, this is where Efectis comes in! Three fundamental skills were required. The first two were the experience of nuclear projects, in particular “ITER” and temperature control, which is Efectis’ specialist area. The third concerned the control of the Helium leak control process, which was achieved thanks to the services of MISTRAS and its level 2 inspectors.

We were very pleased to work in close collaboration with clients with the same high standards as ourselves in terms of quality, safety culture and adherence to schedule. In conclusion, we are pleased to inform you that all the equipment involved in this project is now tested and qualified to take part in the ITER project.

We would like to thank our client JACOBS for allowing us to collaborate in their ground breaking initiative and our prime contractor F4E for their valued contribution.

For more information, please contact france@efectis.com