1/8/2024

Fire test and certification procedure of cables within the scope of EN 50575:

Power, control, optical fibre and communication cables are tested according to the EN 13501-6 to determine the reaction to fire classification. According to the EN 13501-6, cables can have one of the fire classes; Aca, B1ca, B2ca, Cca, Dca, Eca and Fca. In addition to fire classes, smoke classes; s1a, s1b, s1, s2 and s3, droplet classes; d0, d1, d2, acidity classes; a1, a2, a3 are also other classifications that are the subject of this standard.

REACTION TO FIRE TESTS

There are five main test methods for classification according to EN 13501-6; EN ISO 1716, EN 50399, EN 60332-1-2, EN 61034-2 ve EN 60754-2

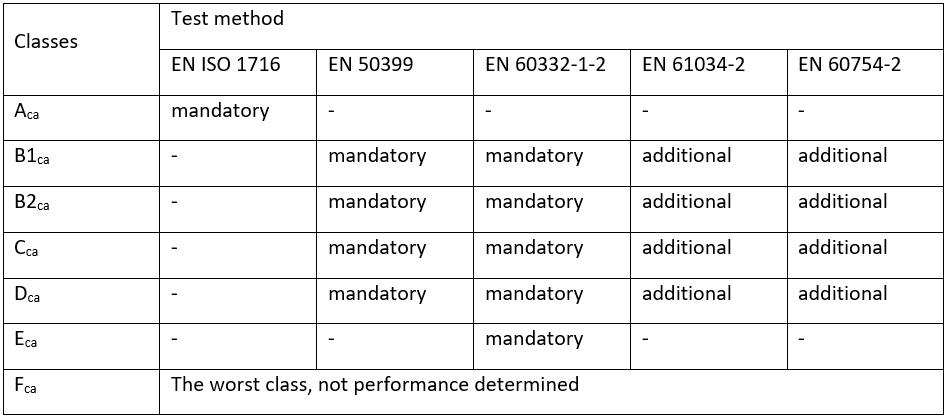

The below table shows Test methods for reaction to fire classes;

In cases where the additional EN 61034-2 and EN 60754-2 tests are not performed, full classification can be obtained. However, these test methods are required for s1a,s1b and a1,a2 classifications.

EN ISO 1716 test method must be applied to each component of the cable excluding the metallic components. In this test method, the gross heat of combustion of the sample is determined in the calorimetric bomb. In order for a cable to meet the Aca class, each component of the cable, excluding metallic components, shall achieve a gross heat of combustion equal or less than 2,0 MJ/kg.

EN 50399 is one of the mandatory test methods for B1ca, B2ca, Cca, Dca classes. In this test method, cables lined up on the surface of a ladder are exposed to a constant flame source for 20 minutes and the flame vertically flaming spread, released heat by the burnt cables, released smoke by the burnt cable, flaming droplets and their flaming times are measured/observed.

EN 60332-1-2 is the other mandatory test method for B1ca, B2ca, Cca, Dca and Eca classes. In this test method, 1 kW propane flame is applied to a small piece of cable with an angle of 45 degrees for 60 seconds, 120 seconds, 240 seconds or 480 seconds, depending on the external overall diameter of the cable. Burnt surface of the cable is measured.

EN 61034-2 is a test method for measuring the smoke density of a cable and determining the additional classifications of s1a and s1b according to EN 13501-6. In this test method, in a sealed cabinet, assembled cables are burnt using an alcohol-water solution.

EN 60754-2 test method is applied to each component of a cable excluding the metallic ones and the results are evaluated for the whole cable. In this test method, each component is burnt separately and released gas is washed. Acidity and conductivity are measured from the washed solution. This method is applied to determining additional classification of a1 and a2 according to EN 13501-6.

FIRE RESISTANCE TESTS

Fire resistance tests of power and signal electrical cables are carried out according to DIN 4102-12, EN 50577 and GOST R 53316 standards. In these three standards, cables rated for voltages up to 1 kV can be tested. Although each of the three standards has their own special conditions, the test methods contain similar applications in many ways.

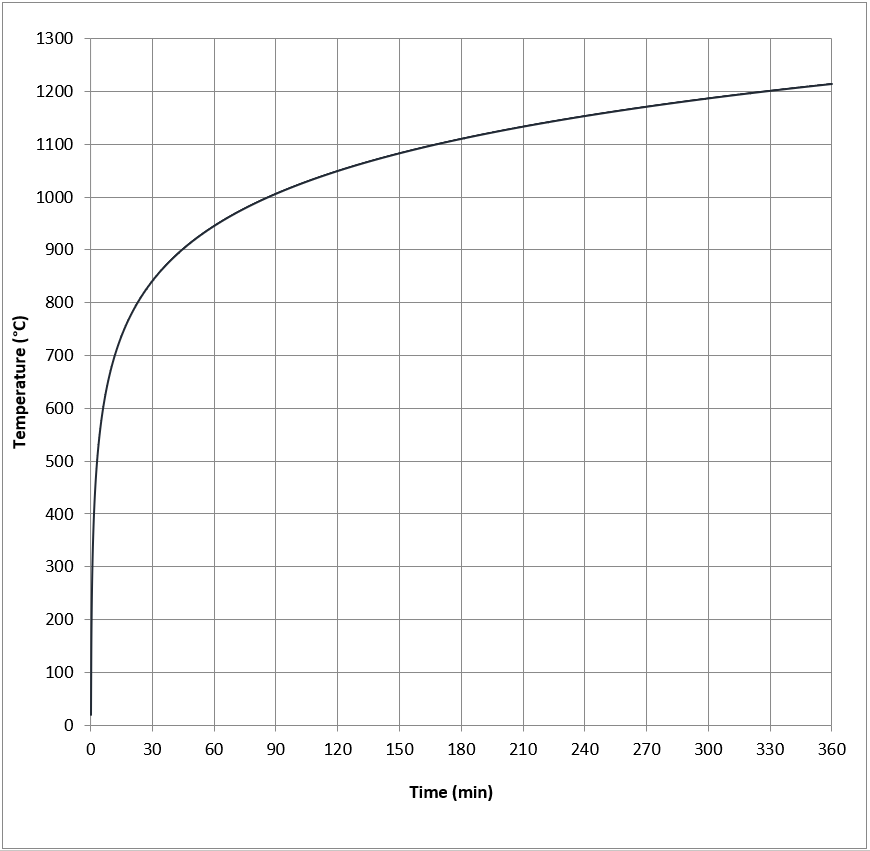

The cables are mounted in the furnace with the minimum dimensions specified in the standard, as they are used in the field of application (wall, ceiling, cable tray, cable ladder and cable duct mounting). Heating is followed according to the temperature-time curve specified in the standard. Below is the temperature-time curve.

| Time (min) | Furnace Temperature (°C) | Time (min) | Furnace Temperature (°C) | ||

| 0 | 20 | 90 | 1006 | ||

| 5 | 576 | 120 | 1049 | ||

| 10 | 678 | 150 | 1082 | ||

| 15 | 738 | 180 | 1110 | ||

| 20 | 781 | 210 | 1133 | ||

| 30 | 842 | 240 | 1153 | ||

| 45 | 902 | 300 | 1186 | ||

| 60 | 945 | 360 | 1214 |

While the cable systems installed in the furnace are heated according to the curves specified in the standards, electric current is pulsed through the cable. The circuit integrity is checked whether it is interrupted or not by the help of the fuses

It is possible to classify the cables as a family when the required tests and conditions are fulfilled as described in the standard For instance, for a 4-core power cable; a cable family can be covered by selecting and testing one cable with the smallest conductor diameter and another with the largest conductor diameter.

Dead weights are hung on the cable supporting systems of the type and weight specified by each standard. The aim here is to test the cable and supporting system in the worst-case scenario.

Classification according to DIN 4102-12 standard; as follows of E30, E60 and E90. On the other hand, EN 50577 test standard is carried out up to 120 minutes according to the “*P classification” specified in EN 13501-3. The classification periods for the GOST R 53316 standard are as follows; 15, 30, 45, 60, 120, 150, 180, 240 and 360.

*Note: Since there is currently no classification for cables in the EN 13501-3 standard, scale of classification cannot be specified. The scales will become clear when the EN 13501-3 standard -the classification standard for the EN 50577 test standard – is published.

Certification of cable & cable carrier systems

The cables to be used in buildings must bear the CE marking according to the EN 50575 standard in accordance with the Construction Materials Regulation. The CE means “conformité européenne” or European conformity, and it is not possible to export products without CE marking. Within the framework of the Customs Union Agreement, it is obligatory for the products to be supplied to the market for the Turkish market to bear the CE marking. Efectis Era Avrasya is authorized for testing and certification according to EN 50575 standard.

The Certificate of Compliance, CoC requested for Qatar, Kuwait and the United Arab Emirates is also an area where Efectis Era Avrasya is authorized.