21/11/2022

The European fire classification system according to EN 13501-1 provides for a series of test methods to achieve a fire classification of A1 to F.

For each fire class other than E and F there are two different test methods needed to achieve a fire classification of A1, A2, B, C or D. The mentioned test methods are the ignitibility test (EN ISO 11925-2), the single burning item (SBI) test (EN 13823), the flooring radiant panel (FRP) test (EN ISO 9239-1), the caloric bomb test (EN ISO 1716) and the non-combustibility test (EN ISO 1182).

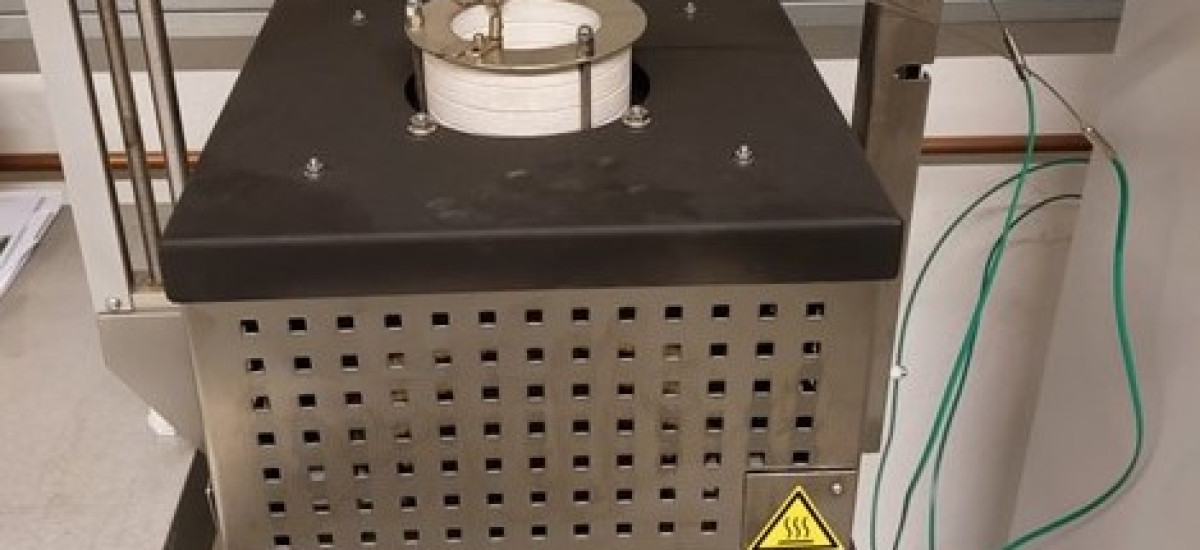

In this newsletter the focus is on the non-combustibility test, which is needed for the A1 classification.This test can be already performed within the Efectis Group. But since November the equipment is available at Efectis Nederland too. It took a long time to acquire all the equipment (i.e. the electronic parts) due to the corona pandemic.

When the accreditation is obtained it will be possible to issue A1 classification reports with the RvA label. The newly available test equipment has been assembled according to the latest test standard, version 2020. The accreditation process was started during this waiting period and is almost complete.

For this test method, a small specimen with more strictly defined dimensions is used: Ø45(+0-2 mm) x 50 mm (+0-3 mm) instead of a specimen with a height of 50±3 mm). Five specimens are needed for a complete test series. The specimen is placed in a refractory tube surrounded by a heating coil and enclosed in an insulated surround. The temperature in the furnace is 750ºC.

In the latest version of the test standard a few modifications have been made, such as the specimen dimensions mentioned above. The inside diameter of the furnace is 100 x 150 mm (d x h). Also, the specimen holder is better defined and needs to be checked at regular periods to verify the weight (15±2 grams).

It should be noted that the furnace is equipped with two temperature sensors, which are positioned close to the furnace wall. The purpose of the extra sensor is to ensure better temperature control so as to achieve a more homogeneous temperature in the core of the furnace.

The minimum and maximum temperatures in the furnace, indicated as Tmin and Tmax, are used to calculate a specific temperature based on the height in the furnace. The temperature values are determined according to a different formula. This results in a little more variation in the total maximum temperature tolerance.

For more information contact Arjo Lock or Bauke Knottnerus