6/12/2024

The Environment Buildings Decree (Bbl) includes requirements regarding the resistance to smoke passage (WRD) between spaces. NEN 6075:2020 is thereby designated as the method of determination, which includes the test method.

The method is based on the principles of standards EN 1634-3 for smoke doors, the European classification Sa and S200 defined by the Commission Delegated Regulation (EU) 2024/1681 and EN 13501-2 establishing the classes of performance in relation to the fire resistance of construction products.

A wall made of Paroc Panel System sandwich panels with stone wool insulation complies with smoke permeability the equivalent of the Euroclasses Sa and S200 and can therefore be used to demonstrate sufficient resistance to the passage of smoke (WRD) between spaces according to the Dutch Building Works Decree (Bbl). This has been demonstrated by Efectis Nederland on behalf of Kingspan / Paroc Panel System with a practical test in the so-called smoke box in its own test laboratory.

In order to realise smoke-resistant partitions, there is now considerable awareness that the various construction components that make up a partition can, and sometimes must, have been tested in a laboratory. This can prove that the smoke permeability of a construction component (or an assembly of construction components) meets the requirements.

Cold or hot smoke

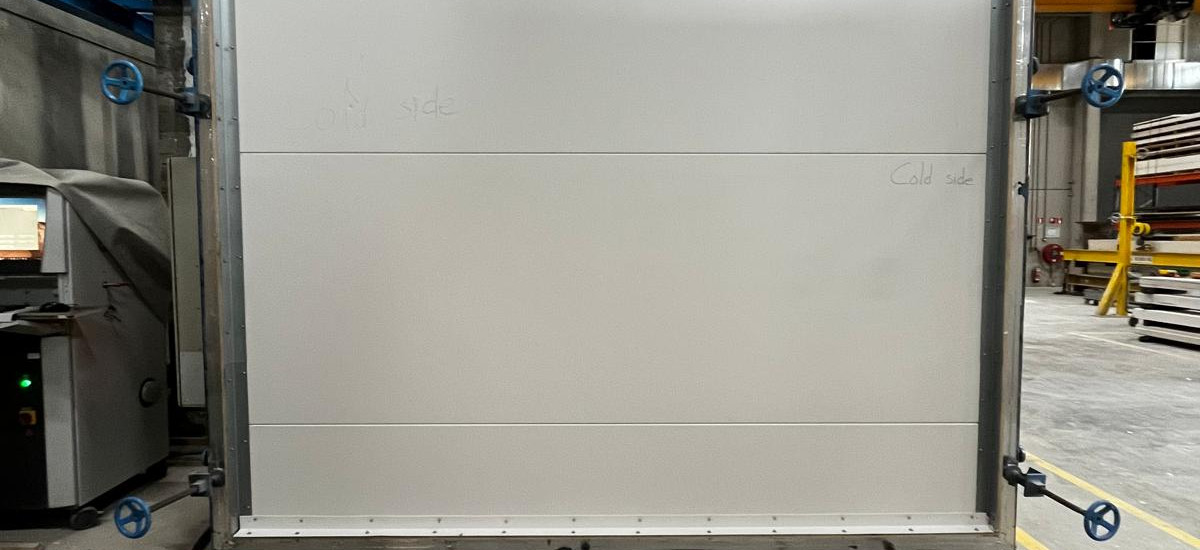

The WRD between spaces depends on the smoke resistance of the partitions. Depending on the situation, this may involve smoke resistance to cold or hot smoke. This means that two scenarios must need to be tested for building products used in smoke barriers. The smoke permeability of a building product is determined using an airtightness test. For this, the test specimen must be installed in a test frame. Efectis has its own test laboratory.

The test is similar to a fire test, but no fire or smoke is produced during the test.

The so-called smoke box, with the test frame containing the test specimen in front of it, is heated and then the leakage loss at various pressure differences is determined. This leakage loss is a measure of smoke permeability.

Efectis carries out the test at a temperature of 20°C (cold smoke) and then at 200°C (hot smoke). This is measured at three different pressure differences: 10, 25 and 50 Pascal. A total of six measurements are involved in one test. The classification for a construction component with a sufficiently low leakage loss is, similar to the classification used for doors, Sa for cold smoke and S200 for hot smoke. This includes doors, hatches, penetrations, dampers, seams and so-called bare separating building components such as the wall of Paroc sandwich panels.

Successful test

The test of the Paroc sandwich panels was successful. Efectis Nederland carried out the test with the smoke box according to NEN-EN 1634-3 in combination with NEN 6075. With this test, the customer can demonstrate that his product complies with smoke permeability classes Sa and S200. This means that the product can then be used in building projects where, according to the Dutch Bbl, the resistance to smoke passage between rooms must comply with Ra or R200.

A nice bonus is that Efectis can test quickly. For a complete application, the total lead time for testing and writing the test report is only about one month. Also, in consultation with the client, based on the scope of application searched by the client, tests were performed to cover as much as possible this domain of application.

In short: Efectis thinks along with you!

For more information, please contact Tim van der Waart van Gulik or Fazwi Mishahrawi