11/12/2023

Foam concentrates and systems used in firefighting play a critical role in protecting buildings and industrial facilities against fire risks. These systems, while having the ability to extinguish fires quickly and effectively, must be operated in compliance with specific standards to ensure maximum performance through regular maintenance and periodic tests.

Turkiye’s membership of the European Customs Union means it is necessary to adhere to the requirements of European Standards (EN). According to EN 13565-2 standards, periodic tests of foam concentrates and foam fire-fighting systems used in firefighting are mandatory. Similar quality tests are also required in NFPA 11, one of the internationally recognized standards. In addition to complying with the requirements of manufacturers and installers, foam tests must be conducted by independent organizations.

Efectis Era Avrasya Laboratory offers a quality analysis service for any foam concentrate and system, regardless of production.

Importance of foam concentrate quality

Foam concentrates used in firefighting must have the correct concentrate quality. This is crucial in controlling and extinguishing fires rapidly. Therefore, foam concentrates and systems should be evaluated at regular intervals.

Why periodic foam tests?

Even foam concentrates stored under the most appropriate conditions and of the highest quality can deteriorate. Foam concentrate degradation can occur for a variety of reasons, such as dilution, contamination, excessive heat and excessive sedimentation.

Which tests should be conducted?

Commissioning tests

Commissioning tests of foam concentrates are conducted to ensure that fire extinguishing systems are installed correctly and can provide the expected performance. These tests are important for assessing the effectiveness of the concentrate system and, if necessary, taking corrective measures.

It consists of:

- Visual inspection

- Pressure tests

- System testing

- Periodic tests

Regular checks and maintenance are required to ensure the operational status of foam fire-fighting systems. These tests are conducted by foam test experts every six months or annually.

Semi-annual inspections

The following tests should be conducted every six months by foam system experts:

- Visual inspection of strainers.

- Functional testing of foam proportioners using water without foam concentrate (when specified by the manufacturer).

- Testing the free movement of all valves and mechanically operated components.

Annual inspections

The following tests should be conducted annually by competent and trained foam laboratory personnel. Many of these tests are conducted in the laboratory due to temperature criteria, conditioning, or the need for a sterile environment. Samples should be taken by technical staff or foam experts from Efectis Era Avrasya in accordance with the sampling instructions and sent to foam laboratories in appropriate containers.

The following tests are conducted to measure foam quality:

- Foam type and appearance

- Specific gravity

- pH Value

- Sedimentation

- Spreading coefficient

- Viscosity

- Determination of freezing point

- Accelerated aging

Quality tests as described above result in a report, stating “Pass” or “Fail“. If the foam concentrate report does not pass quality control tests, it should immediately be replaced with foam concentrate that has passed fire testing according to the relevant section of TS EN 1568 by the same type suitable for use and approved by an authorised organisation.

If any foam concentrate sample is found to perform at the limit, small-scale fire tests need to be conducted in the laboratory.

Performance tests

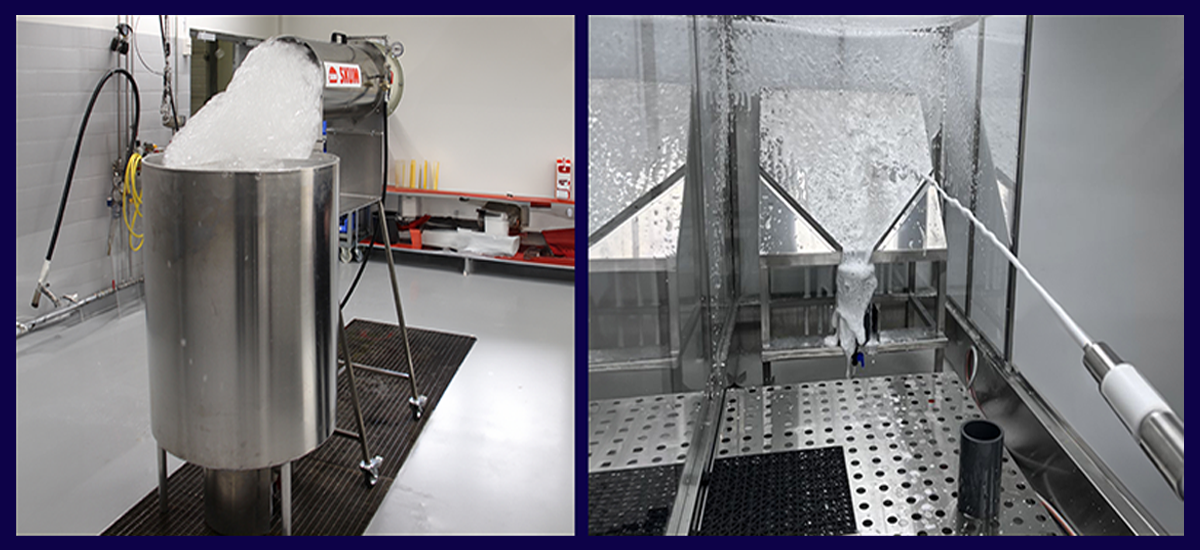

In addition to evaluating the physicochemical properties of foam concentrates, performance tests are conducted to show us how effective the foam sample will be in extinguishing flammable liquid fires.

- Expansion ratio and drainage time: the expansion ratio indicates how much the foam concentrate increases when mixed with water. This test is essential in ensuring that the concentrate is mixed correctly and operates effectively within the fire extinguishing system. Drainage time indicates how the foam flows from the surface. This test assesses the foam’s effectiveness by evaluating its post-fire drainage time.

- Induction test (for system calibration): this test determines whether the fire extinguishing system is properly calibrated. Tests are conducted at maximum and minimum system design flow rates, including proportioning and related connection components. The accuracy of foam proportioning should be within the tolerance specified in TS EN 13565-1.

- Alcohol tolerance test: this test assesses whether the foam concentrate is effective against flammable liquids like alcohol. Alcohol can reduce the effectiveness of some foam concentrates.

- Small-scale fire performance test: this test simulates a real fire scenario and evaluates the effectiveness of the concentrate. In cases where quality tests indicate that a low-expansion foam concentrate sample performs at the limit, small-scale fire performance tests are conducted in the laboratory according to TS EN 1568-3 and TS EN 1568-4.

Additionally, induction tests for accurate foam extraction and system calibration should be performed. Finally, if foam quality tests indicate that a low-expansion foam concentrate sample is performing at the limit, small-scale fire tests should be conducted in the laboratory according to TS EN 1568-3 and TS EN 1568-4.

Flow tests

Flow tests are conducted to ensure that fire extinguishing systems are functioning correctly, there are no obstructions in nozzles, valves are working correctly, and foam has reached the required protection area.

For more information, please contact: turkiye@efectis.com