7/3/2023

When people think of dampers, the types that generally come to mind are fire and smoke control dampers. Of course, different institutes also define several sub-types for each damper type, such as volume control dampers and corridor dampers.

However, when Efectis Era Avrasya was approached with a demand regarding tunnel dampers, the aim was clear. The specifications also stated that the main test should start from -5 °C and reach 250 °C in no more than 20 seconds. With its expertise – and a bit of creativity – Efectis Era Avrasya was able to tailor a new test method for the stated conditions.

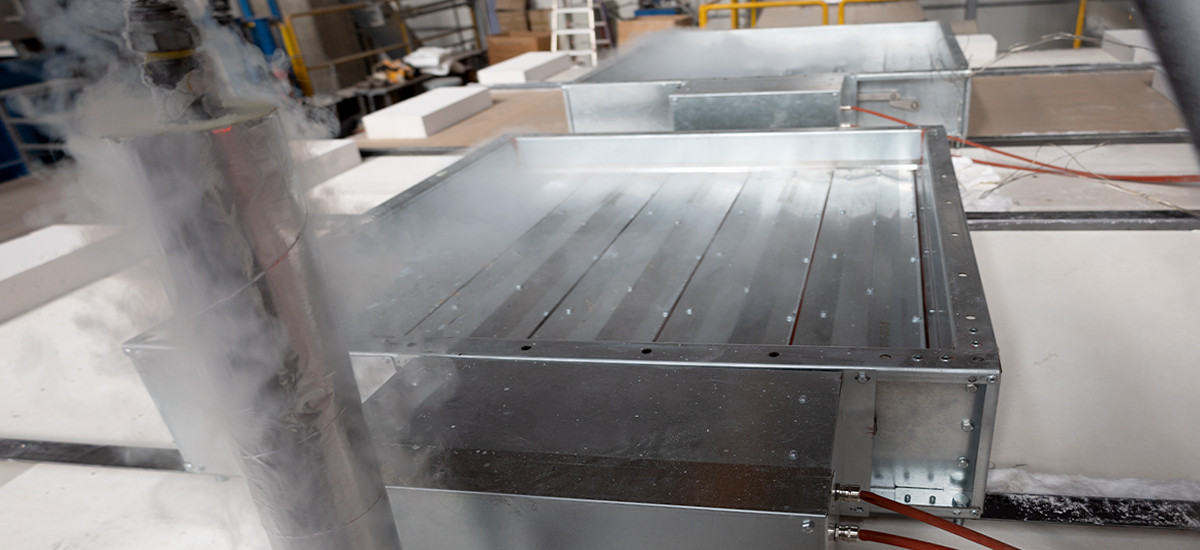

Some auxiliary test demands, such as leakage tests, were very similar to procedures set down in EN 1366-2/10 and UL 555 series standards. Some others, such as mechanical stability tests under high pressure, did not exist, but were also simple to create with larger equipment. Thermal shock, however, presented the biggest challenge. Potential unforeseen problems that were solved with a combination of theory and trial-error included cooling the volume without damaging the internals, igniting the furnace with displaced oxygen, disconnecting the coolant safely after commencing the test, and reaching the desired temperature within certain time limits.

The desired conditions were achieved for transferring the liquid nitrogen into the furnace via insulated pipes. The furnace surpassed the 250 °C mark between the 19th and 20th seconds and by this frame, initially temperature was -19.7 °C. Due to the unpredictable and unrepeatable nature of fire resistance tests, these exact values might not be reached every time, but the results prove that there is even some margin for error.

By performing the first thermal shock test of this calibre in Türkiye, Efectis Era Avrasya once again demonstrates its ability to adapt and develop new methods and its dedication to continuing to lead the sector.

For more information, please contact: turkiye@efectis.com