6/10/2025

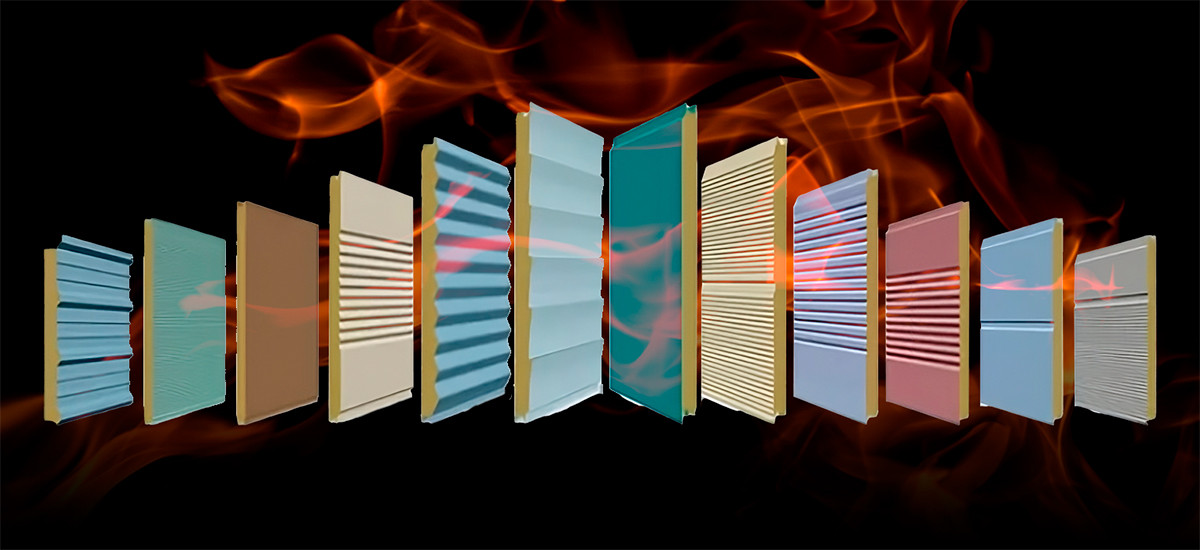

Sandwich panels are widely preferred in both industrial and commercial buildings due to their advantages in energy efficiency and rapid installation. The EN 14509:2013 standard defines these panels as “self-supporting double skin metal-faced insulating panels.” The scope of the standard covers a wide range of applications, including roof and façade cladding, partition walls, ceilings, and cold storage facilities.

The core materials used within this scope include PUR, PIR, EPS, XPS, PF (Phenolic Foam), glass wool / mineral wool (GW), and stone wool (SW). This diversity allows manufacturers to develop products with different performance levels. However, panels with curved surfaces, multi-layered designs, or perforations are excluded from the standard, clearly defining its limits of application.

Key Performance Characteristics

Clarifying the scope also raises the question of which performance criteria the panels will be evaluated against. EN 14509:2013 defines several performance characteristics to ensure the suitability of sandwich panels for their intended use. The main performance criteria include:

- Thermal conductivity and thermal resistance

- Acoustic insulation and mechanical strength

- Reaction to fire and fire resistance

- Water and air tightness

- Dimensional tolerances and durability

These characteristics must be properly determined according to market needs and declared by the manufacturer through a Declaration of Performance (DoP).

Conformity Assessment and AVCP Systems

Defining performance criteria alone is not sufficient. To ensure these characteristics are reliably placed on the market, conformity assessment mechanisms must also be implemented. Under EN 14509:2013, this process is carried out through Assessment and Verification of Constancy of Performance (AVCP) systems.

| AVCP System | Manufacturer Responsibilities | Notified Body (NB) Responsibilities |

| System 1 | – Establish and maintain Factory Production Control (FPC) – Conduct regular FPC testing – Prepare DoP and affix CE marking | – Approve type testing – Audit production and FPC – Apply continuous surveillance |

| System 3 | – Establish and maintain FPC – Conduct regular FPC testing – Prepare DoP and affix CE marking | – Carry out and report type testing – Does not audit production |

| System 4 | – Perform type testing internally – Establish and maintain FPC – Conduct regular FPC testing – Prepare DoP and affix CE marking | – No role |

The system to be applied is determined by the intended use of the product and its risk level. The criteria for selecting the AVCP system are explicitly defined in Annex ZA of the harmonized standard.

Assessment of Fire-Retardant Use

For sandwich panels produced under EN 14509:2013 with a polyurethane or polyisocyanurate (PUR/PIR) insulation core, manufactured directly in the production line of the sandwich panel producer, and with a reaction-to-fire class of “C” or better (A1, A2, B):

- If the panel manufacturer directly adds a fire retardant or carries out an activity to improve the reaction-to-fire classification, AVCP System 1 must be applied.

- If the panel manufacturer does not directly add a fire retardant and it cannot be confirmed whether any of the raw materials provided by the supplier contain fire retardants due to confidentiality, AVCP System 1 must again be applied.

- If the panel manufacturer wishes to apply under AVCP System 3, they must provide the Notified Body/Technical Assessment Body with a written declaration, such as the example below:

“All our chemical raw material suppliers confirm that the raw materials used in the production of polyurethane or polyisocyanurate (PUR/PIR) insulation cores do not contain fire retardants (flame retardants). Therefore, the application of AVCP System 3 is appropriate.”

Manufacturer Obligations

Manufacturers’ obligations under the CPR include:

- Preparing a technical file and the Declaration of Performance (DoP)

- Establishing and maintaining a Factory Production Control (FPC) system

- Ensuring performance consistency in serial production

- Implementing product recall and complaint management for nonconforming products

- Submitting technical documentation to authorities upon request

CE Marking and Market Impact

The EN 14509:2013 standard secures the performance of sandwich panels and establishes a common reference point for both manufacturers and users. Through conformity assessment systems, compliance with essential safety requirements and constancy of performance are verified. The CE marking provides both reliability in the marketplace and a competitive advantage. With growing demands for energy efficiency, fire safety, and sustainability, the importance of this standard is expected to further increase in the future.