4/6/2018

The tunnel rings are connected to each other by metal rings, and seismic joints are being used to avoid the potential risks of an earthquake. Hence similar fire performance is expected in all of the tunnel segments. For this reason, the temperature of the metallic components and the air temperature between the rubber gasket and the metal ring connections are expected to be limited for avoiding any damage.

The aim of this project was to evaluate the insulation performance of the seismic joint structure.

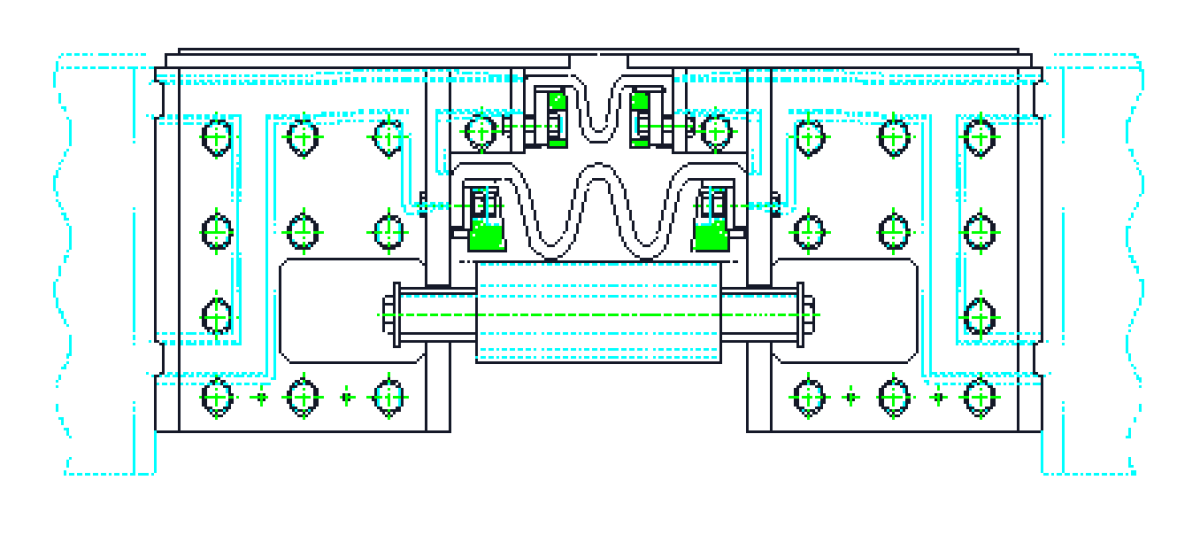

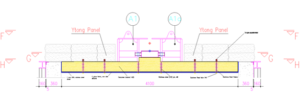

The seismic joint consisted of two identical parts. Connection between the two parts was provided by steel pipes covered by steel box profiles. The pipes had limited movement capability between two ring sections which simulates real scenario. Underneath of the seismic joint structure overlapping the supporting construction were covered by ceramic fibre insulation blankets. The insulation was wrapped in fibreglass textile. Each layer of the ceramic fibre blanket was fixed by stainless steel bolts, nuts and washers. Stainless steel sheets were used as a decorative cover of the seismic joint over the insulations.

The outer joint was wrapped in ceramic wool blanket in order to keep the hot air inside the joint for the worst case scenario.

Two identical parts had free movement in order to simulate the free deflection when heated. The thermocouples were placed on the steel pipe connections and suspended in the air below the rubber gasket.

RABT-ZTV fire curve for trains was realized during the heating. As a result of the test, the temperature at any measurement location did not increase approximately more than 10 °C.

Contact: Ulker Verenel – [ulker.verenel@efectis.com]